Automatic ring bending machine is a kind of mechanical equipment supporting the metal spiral winding gasket production, it is a special equipment for the production and processing of metal spiral winding gasket Inner and outer rings.

Metal ring welding machine for the process of welding metal ring seams with a width of 5 to 50 and a thickness of 3 mm. The drive system is completely controlled by stepper motors and the control is done by a touch screen PLC.

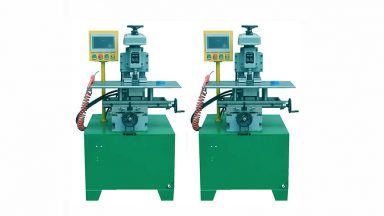

The metal rings joint milling machine is mainly used for rough milling of joints above the ring plane after welding of metal rings, reducing the usual workload after grinding. Its data is entered by a touch screen PLC with automatic control.

For milling grooving at 90 degrees around the inner circumference of ≥φ150 outer rings. The roller unit is pneumatically controlled, with a wide range of pressure adjustment and very simple operation. The feed is controlled by electronic stepless variable speed, which can adapt to the needs of different materials processing.

The outer ring is first pressed into a conical shape, which makes the inner diameter of the inner ring expand, and then the winding body is installed to flatten the ring, thus completing the assembly.

For grinding and polishing the welded joints of metal rings after welding. The machine is semi-automatic, but highly efficient. During the polishing process, burrs and scratches are polished on the surface of metal rings with a diameter of 150 mm or larger.

For the processing of 90 degree chamfers on the inner and outer circumference of ≥φ250 wound gaskets. The pressing device adopts pneumatic pressure, with a large adjustment range and simple operation. Feeding adopts electronic stepless to meet the processing requirements of different materials.

Small special lathes can process inner and outer rings of swg easily and with great efficiency and speed for size small than 300mm.

Simple to operate and suitable for the production of small batches and multiple sizes of gasket rings.